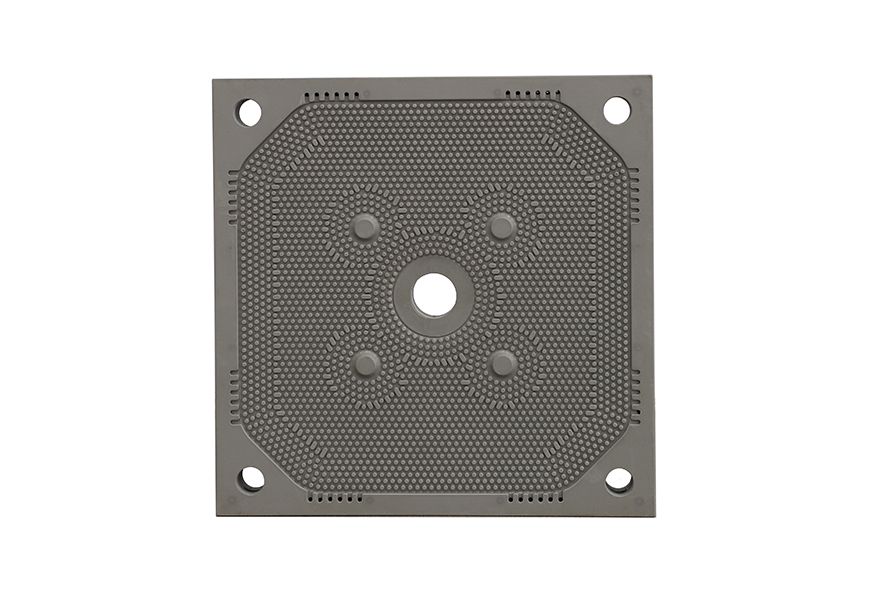

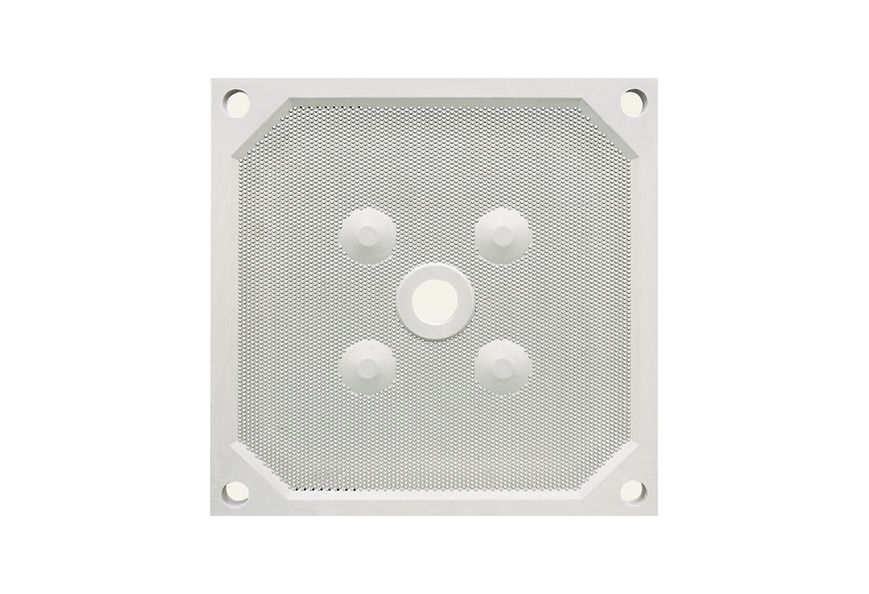

Filter Plate

Filter plates are an important part of a filter press. They hold the filter cloth and separate the liquid from the solids during the filtration process. Different plate styles are compatible with various filter press designs.

When the filter press is closed, each plate seals together to form a mold that holds the filtered solids.

In our manufacturing, we employ cutting-edge technology and top-tier polymer resin materials. The standard material for our plates is PP-copolymer, yet we provide a range of reliable alternatives based on your specific requirements and the intended use of your filter plates. These options encompass PP-homopolymer (optionally with glass fiber reinforcement), nylon reinforced with glass fiber, and PVDF containing carbon filler.

Our production techniques, coupled with our machining and finishing capabilities, ensure superior quality products delivered promptly and at competitive prices. By managing all stages of the process internally, we uphold stringent quality control standards.

Zhongda Bright offers a comprehensive range of filter plate types and materials, including chamber filter plates, membrane (diaphragm) filter plates, plate and frame and specialty filter plates such as vacuum membrane filter plates.

Zhongda Bright's filter plates are perfect for any application that requires liquid-solid separation, including mining and mineral processing, chemical manufacturing, food and beverage, industrial wastewater, and many more. Our filter press plates have gained a global reputation for quality, craftsmanship, durability, and precise specifications. We provide a comprehensive range of filter plate types and materials to fit all OEM presses.

Zhongda Bright offers both standard and custom filter plate designs, tailored to your market and application. Zhongda Bright can design filter press plates that improve cake drying and washing efficiency, or help combat abrasive conditions. Ask us about our custom solutions or our OEM replacement plates.