Sustainability

ZhongDa Bright Filter Press Co., Ltd. provide a Sustainable Solution to Fine Material Waste water Aggregate and minerals processing producers typically send the fine material waste from their wet processing plant to settling ponds or tailings dams, which provide a space for the solid material to settle and allow the recovery of reusable water.

Usually, these ponds are difficult and costly to manage in terms of maintenance, since full ponds require the periodic removal of material. Permitting new ponds to hold the additional fine material waste can be a challenge as well. Ponds can also take up quite a bit of valuable land space, potentially covering up mineable reserves.

A sustainable solution

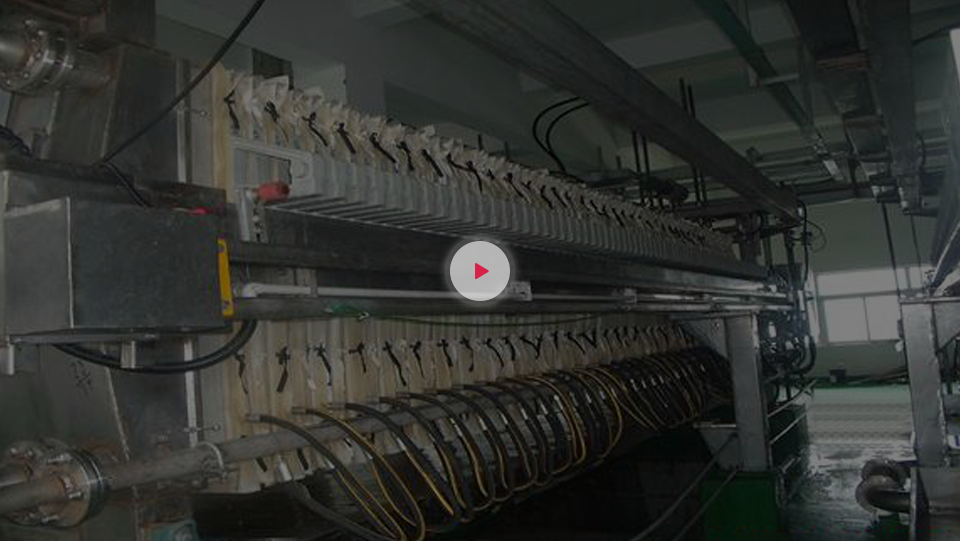

ZhongDa Bright Filter Press Co., Ltd. provide many benefits to aggregate producers who want to manage their waste material more efficiently and effectively. They separate solids and liquids in slurries to create dry, stackable material and recover process water that can be reused in the wet plant.

ZhongDa Bright Filter Press Co., Ltd. gives the customer the opportunity to completely eliminate a settling pond and the associated higher cost of managing that pond and the waste material in it,""It gives them the potential of recovering the maximum amount of reusable water. It generates a much more easily managed solid waste material, and there's some possibility it could create a new salable product."

Eliminate settling ponds

By separating the fine material waste slurry into a dewatered solids portion and a reusable liquid portion with Bright Filter Press, producers can eliminate the need for settling ponds, as well as the cost associated with maintaining those ponds. You also free up a lot more available space."

Recover reusable process water

Filter Presses recover between 80-90% of the water volume from a slurry feed that's 30-45% solids. The recovered water can be reused immediately in the upstream wet processing plant, reducing the need to rely on municipal supplied water or a nearby groundwater source and the cost associated with purchasing/pumping that water.

From a water usage standpoint, the Filter Press is a lot more effective way to recover water, especially in areas where water is scarce or expensive, being able to recover as much water as possible to reuse is really important."

By recycling water with Bright Filter Press, the need for fresh water for processing is minimized. It creates a nearly closed-loop system where the plant keeps reusing its own process water to operate.

Create a new salable product

Another benefit of the dewatered solids besides being easier to manage is the potential to create a salable product from the waste material. Rather than sitting in a settling pond taking up space, the dewatered solids could be a potential source of additional revenue.

Use land more effectively

The lifecycle of a mining or aggregate location takes usable material out of the ground and separates it from the waste material, which then has to be placed back into the ground. Bright Filter Presses allow the solid waste material to be placed permanently on the mine site much quicker.

Using Bright Filter Press allows you to more quickly place the material where it's going to stay forever — you won't have to dig it up again, won't have to process it again. The land could be reused once the site is no longer in operation a lot more effectively."

Benefits Of Bright Filter Presses

Bright Filter Presses offer a way to eliminate settling ponds to free up land space and/or mineable reserves, which helps with permitting costs/restrictions. They create a more manageable dewatered solid material with reduced handling costs and the potential for sale. They recover immediately reusable process water for those facing limited water availability or high fresh water usage and cost.